Ather Energy announces second manufacturing plant in Hosur, to expand capacity to 400,000

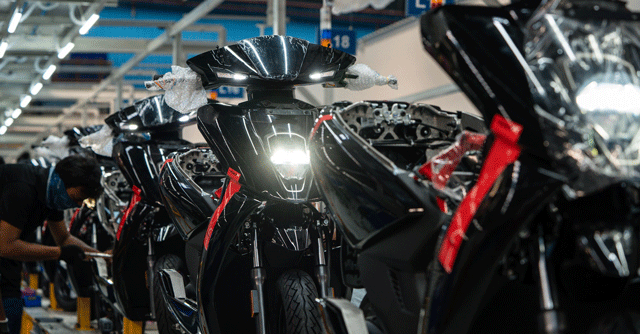

Indian two-wheeler EV company, Ather Energy today announced that it will set up a second manufacturing plant near its present facility in Hosur, Tamil Nadu. With the new plant, Ather expects its total annual two-wheeler production capacity to hit 4 lakh units, once the latter is fully operational. It currently produces 120,000 units per annum.

The facility is expected to become operational by the end of 2022. Ather already has its first manufacturing facility in Hosur itself, from where it has the capacity to produce 1.2 lakh electric scooters every year.

Tarun Mehta, co-founder and chief executive of Ather Energy, said that despite the company’s first plant becoming operational earlier this year, it is already operating at full capacity. “Our retail footprint is set to grow by six times in the coming quarters. Within 10 months of opening our current facility, we are operating at full capacity,” Mehta said.

Ather’s announcement comes as scooter rental startup, Bounce, gears up to announce its own electric two-wheeler, called the Bounce Infinity. The company has announced a partnership with smart parking solutions startup, Park+, to setup a battery swapping infrastructure across 3,500 outlets in 10 cities to start with.

Bounce chief executive, Vivekananda Hallekere, has said that within two years, the company’s battery swapping infrastructure will be able to support 1 million electric scooters on road.

Ather, on the other hand, offers a non-removable battery pack on both its scooters, the 450 Plus and the flagship 450X. The company assembles its own battery packs at its already functional Hosur plant, and the upcoming facility will ramp up volumes for it as well. Ather Energy also imports the cells for its batteries.

India presently does not have any cell manufacturing facilities. The country’s first cell manufacturing factory, which is being setup by Japan’s Amperex Technology Limited (ATL) in Gurugram, Haryana, is expected to become operational by September 2022, Nitin Gupta, chief executive officer of recycling firm Attero Recycling told Techcircle last week.

The Indian government has extended a production-linked incentive (PLI) scheme to boost advanced chemistry cell (ACC) battery manufacturing in the country. In September, Indian multinational Exide Industries also said that it aims to explore ACC manufacturing in the country to cash in on the PLI scheme.

Ather Energy is also eyeing an initial public offering (IPO) within the next 24 months, according to reports. The company seemingly expects to turn EBITDA (earnings before interest, taxes, depreciation and amortization) positive by then. At present, the company has claimed to have seen 20 percent month-on-month growth in sales since November 2020, standing at revenue run-rate of $100 million.

According to today's announcement, Ather aims to invest Rs 650 crore (approx. $86.6 million) in the next five years across operational and production processes. The latter includes expanding its footprint in India to have 150 operational experience centres across 100 cities in India by March 2023.